Innovative Packaging Solutions for the Automotive Industry

TRG's Automotive Division is "Driven" to Perform

The Royal Group (TRG) offers comprehensive automotive packaging solutions tailored to meet the diverse needs of OEMs and suppliers. With over 30 years of experience, TRG specializes in designing and manufacturing packaging that ensures the safe and efficient transport of automotive components.

Custom Packaging for OEMs, Tier 1 & Tier 2 Suppliers

Through fabrication of metal racks, plastic dunnage, foam, and expendable packs, TRG has the capabilities along with a multitude of materials and designs to help support your needs. TRG provides packs and automotive parts packaging for the following uses: export packs, service and dealer packs, and returnable back-up packs.

Our Packaging Capabilities

Our plastic solutions come in various thicknesses (2–10mm) and materials, including spunbond, Tyvek, and brush-fab, ensuring Class A surface protection.

Class A Surface Protection

- Spunbond

- Brush-fab

- Tyvek laminates

Material Thicknesses

- 2 to 10 mm

We provide precision-cut foam inserts made from materials like EPE, EPP, and EPS, offering superior protection for components such as windshields, EV chargers, and dashboards. Class A & Class B surface protective packaging utilizing:

- Crosslink

- EPE

- EPP

- EPS

Material Densities

- 1 to 10 pounds

TRG hand-assembles fabric dunnages and bag systems into a variety of outer containers.

- Spunbond

- Brush-fab (brush nylon)

- Tissue-lam

- Tyvek

- Vinyl

- Autoguard and softshield comparables

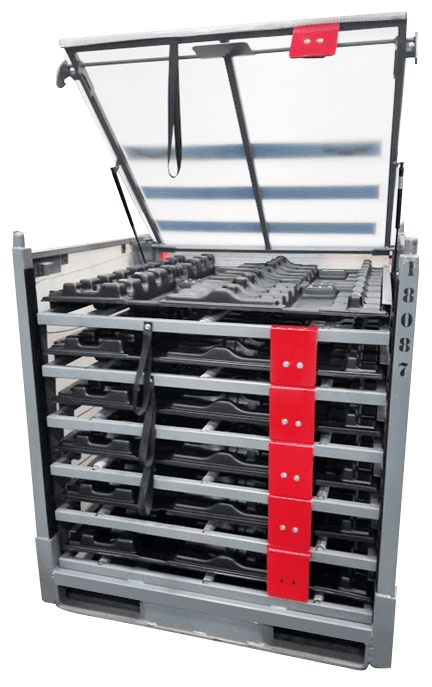

Engineered for durability, our metal racks are ideal for transporting heavy or sensitive automotive parts, reducing waste and lowering long-term costs.

- WIP Shipping Racks

- Mass Production Shipping Racks

- Low-High Complexity

Designed for one-time use, these packs are perfect for international shipping and dealer deliveries, ensuring components arrive safely.

Expendable automotive packaging from The Royal Group is designed to provide secure, cost-effective solutions for transporting and protecting automotive parts. Engineered for one-time use, this packaging ensures durability and reliability during transit, helping safeguard components from damage while optimizing shipping efficiency. Tailored to meet industry demands, our solutions offer seamless integration into your supply chain.

Check Out Our Work

We have developed a diverse range of packages, displays, and containers tailored to various applications, including motor parts and more. Our commitment to innovation and flexibility enables us to deliver cutting-edge packaging solutions specifically designed for the auto parts industry. Our expertise encompasses packaging solutions for a wide array of automotive components, such as windshields, engine parts, lead/acid batteries, wheels, transmissions, truck bed covers, exterior accessories, motors/alternators, radiators, fans, interior molded parts, roof racks, tires, headlights and taillights, side/rear mirrors, ADAS components, dashboard panels and displays, catalytic converters, EV chargers, body panels, bumpers, interior panels, spoilers, and displays. Our packaging solutions are designed to accommodate components of varying sizes, shapes, and fragility, ensuring optimal protection and efficient handling throughout the supply chain. Below are some examples showcasing our previous work.

Partner with TRG for reliable, efficient, and sustainable automotive packaging solutions. Our team is ready to assist you in developing packaging that meets your specific needs.

- Original Equipment Manufacturers (OEMs)

- Tier 1 & Tier 2 Automotive Suppliers

- Electric Vehicle (EV) Component Manufacturers

- Automotive Aftermarket Parts Suppliers

Looking to create the perfect packaging for your automotive parts?

A Delicate Approach to Glass Packaging

Eliminating possibilities of breakage at the end customer is given the utmost consideration while designing glass packaging. The glass product must reach the end-user damage-free while considering associate safety through the supply chain.

If you have a part, we can make a pack!

Did you know a single vehicle can have up to 30,000 parts? Our expert automotive team specializes in designing custom packaging solutions to safely secure and organize parts of all shapes and sizes, ensuring they stay protected and ready for delivery.

Let us take care of your packaging, so you can focus on delivering quality!

foam, packaging, transport, supply chain, dunnage, vehicle, pallet, sustainability, plastic, logistics, expendable packaging, cost, automation, inventory, customer, lean manufacturing, efficiency, electrostatic discharge, bubble wrap, carbon footprint, environmentally friendly, carbon, sustainable packaging, reusable packaging, wood, sealed air, steel, ecological footprint, returnable packaging, automotive components, engine, corrosion, brand, corrugated box design, composite material, polyethylene, plastic container, polypropylene, automotive aftermarket, printed circuit board, demand, polystyrene, cargo, retail, windshield, factory, food packaging, regulatory compliance, exhaust system, packaging waste, automotive lighting, volatile corrosion inhibitor, supply chain management, shipping container, chassis, standardization, sonoco, packaging automotive, crate, carton, corrugated, parts packaging, metal, folding carton, cardboard, bumper, market analysis, quality management, consumer, axle, paperboard, transmission, methodology, quality management system, international paper, corrugated plastic, ds smith, weight

automotive packaging solutions, automotive packaging companies, automotive parts packaging solutions