Sustainability

Our Sustainability Policy is WaterFiberForestEnergy

TRG strives to be a responsible steward of the environment with a forward-thinking business model building on opportunities to create a balanced ecosystem utilizing the 4 pillars of our Sustainability platform; Forest, Fiber, Water, & Energy.

Our corporate environmental reduction goal is to reduce energy, water, & waste by 15% by 2035 (baseline year of 2023)

Our Goal

25%

SUPPORT HEALTHY FOREST by expanding our measure of wood sourced through sustainable forestry programs

Successes

GROWING 25% more than is being removed from the wood basin.

TRACK all wood purchases via verified tracking system.

FOREST ENHANCEMENT activities provide nearly 2/3 of our wood supply.

FOREST

FIBER

Our Goal

OPTIMIZE OUR FIBER YIELD

PROMOTE INNOVATIVE, SUSTAINABLE DESIGN PRINCIPLES

REDUCE AND REUSE PAPER WASTE generated in our facilities

Successes

DESIGN packaging for efficient use of new & recycled materials maintaining structural integrity/maximizing trailer & warehouse space.

DIVERT all waste from production to recycling mills. (Over 7MM tons of materials diverted from landfills)

STANDARDIZED use of recycled mediums.

DEVELOP higher strength grades requiring less fiber.

UTILIZE fully recyclable flexo & digital inks.

Our Goal

15%

REDUCE WATER USAGE while seeking new ways to refine our water conservation methods and ensure water output is aligned with community needs.

Successes

SAVE 3MM gallons of water annually through continuous chillers on our corrugators.

UPGRADE to WaterSense technology with all renovations and new builds at TRG facilities.

Water

Energy

Our Goal

REDUCE GREENHOUSE GAS EMISSIONS by 15% throughout our facilities by the year 2035 (baseline year of 2023)

INVEST IN ENERGY-EFFICIENT CONVERSION EQUIPMENT in our production process

Successes

TRANSITION lighting to LED & Motion Sensitive Lighting. 75% complete conversion to LED.

CONVERT our forklift fleet to electric power source.

UPGRADE outdated HVAC systems/renovations/green builds with energy efficient units.

INVEST in energy-efficient conversion equipment.

The Life Cycle of a Box

Sustainability is at the heart of TRG’s approach to packaging. From using responsibly sourced materials to efficient production that reduces waste, we focus on minimizing our environmental footprint. By committing to sustainable practices at every step, we minimize our environmental impact and support a closed-loop system that conserves resources and promotes a greener future.

Featured Case Studies

-

Case Study

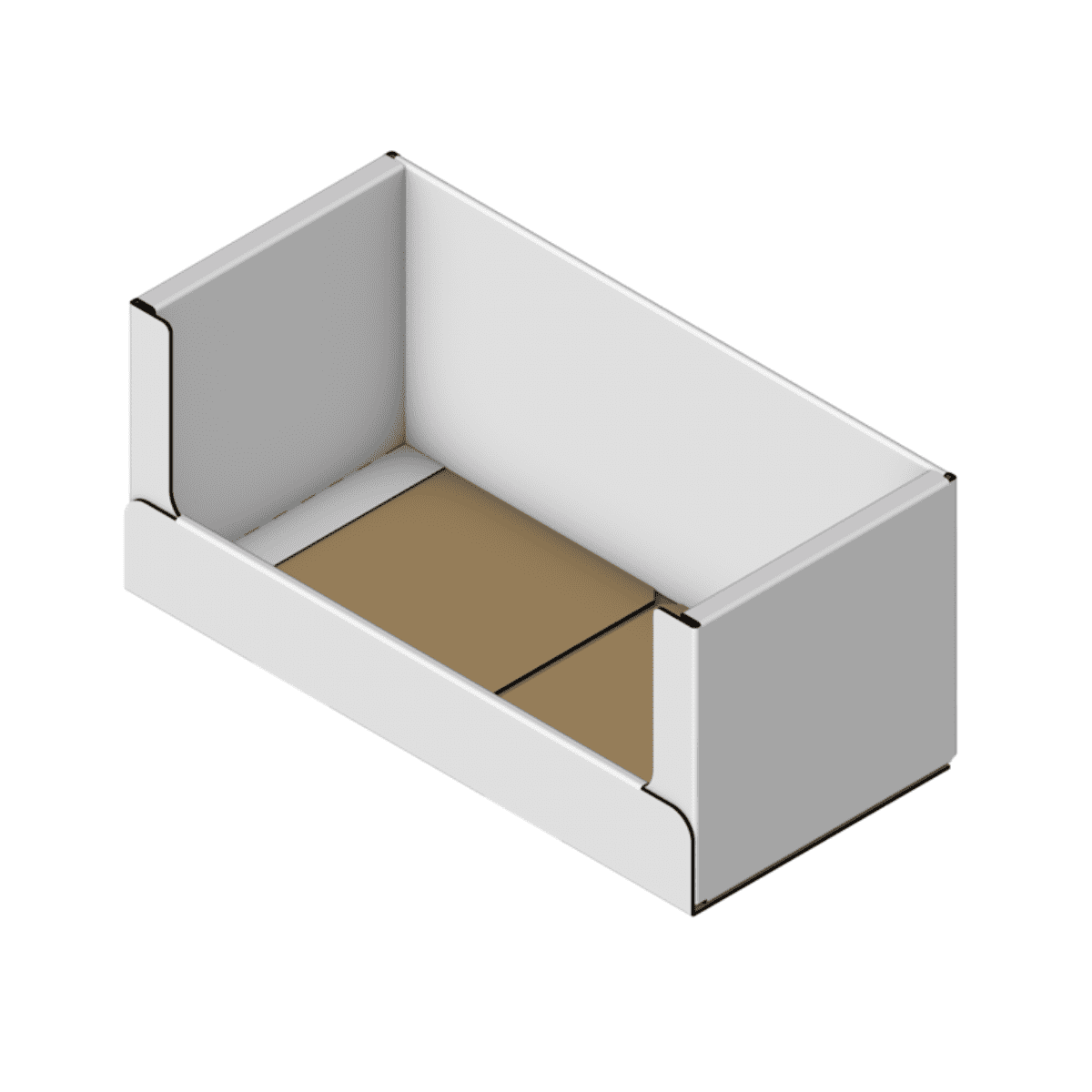

Club Tray

1 component; 17% material reduction

Parity compression strength to incumbent

Annually saves 2.1MM Sq. Ft. board.

-

Case Study

Cross Aisle Pallet

Reduced total # of components to 15 from 35

Corrugate reduction 12%

Maintained structural integrity & performance

-

Case Study

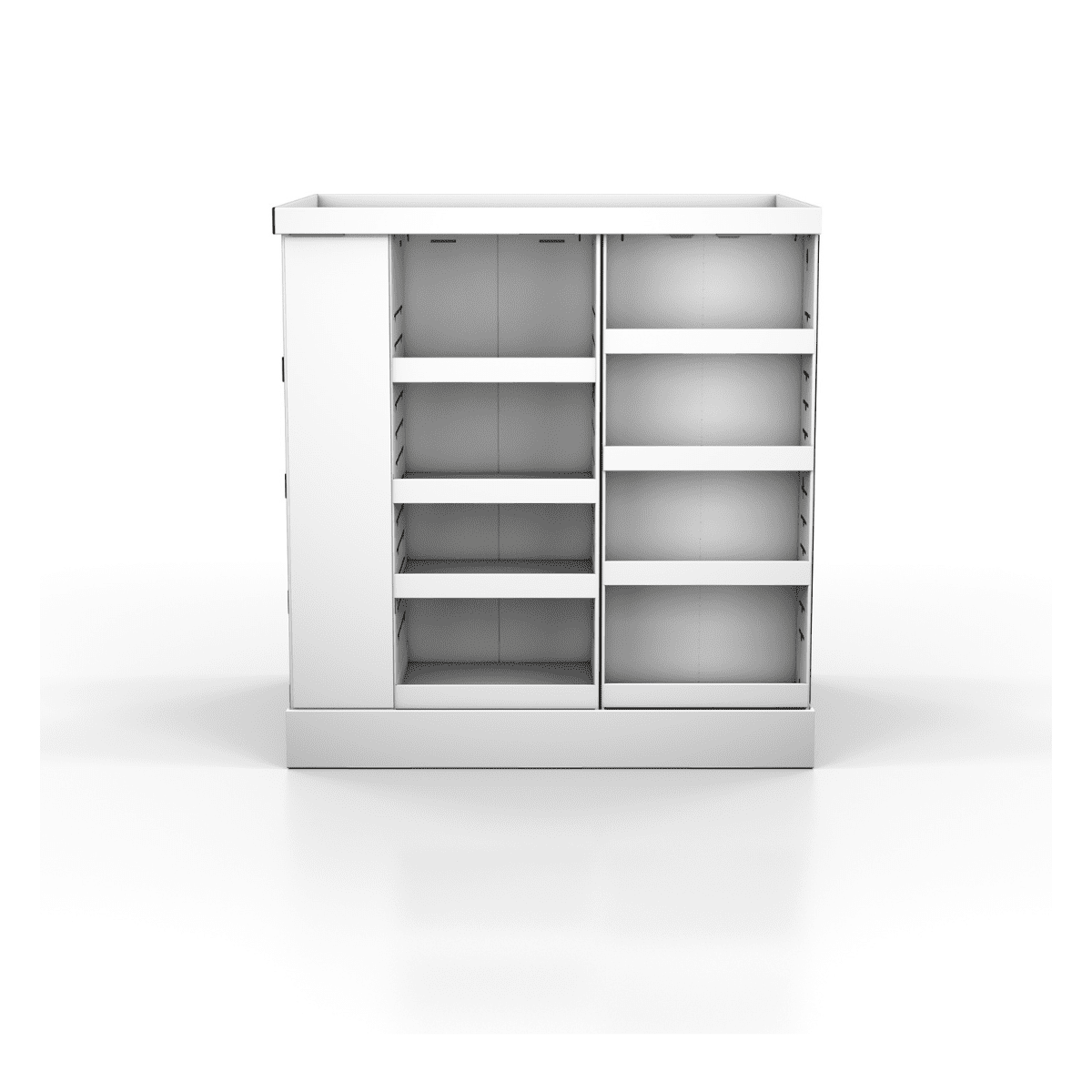

Custom Corrugated Bin

Locking Bottom/Top Cap

Supports 250-300lbs product load.

Compatible with customer racking system.

100% recyclable.

Reduced trailering & warehouse space.

-

Case Study

Toy Pallet

Reduced # of components from:

70 corrugated / 6 plastic to 42 corrugated / 0 plastic

Maintained structural integrity & performance

-

Case Study

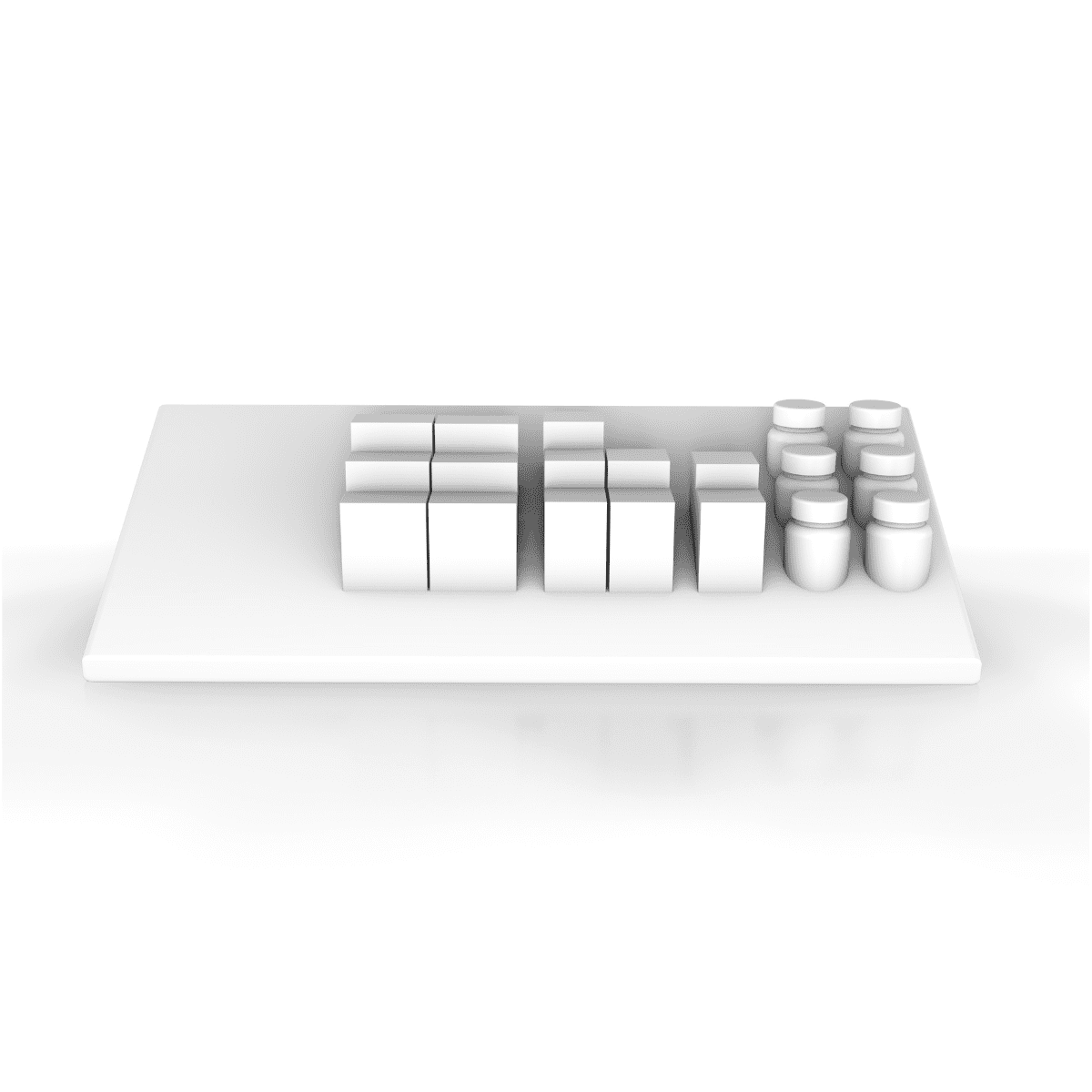

Shelf Tray

Reduced # of components from 8 to 5

Reduced printed components from 3 to 1

The Power of Green

Many of our corrugated facilities also focus on making Green Choices including: